View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

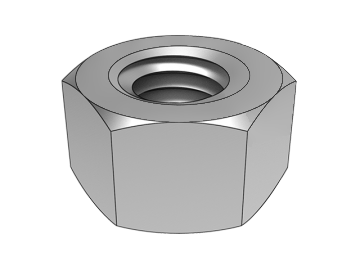

Hex flange nuts are preferred over traditional nuts in several applica...

read more

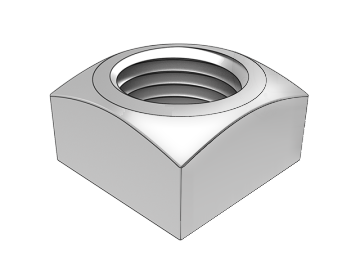

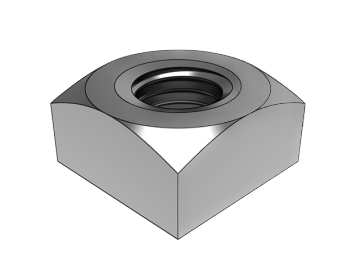

Square nuts and hex nuts exhibit similarities and differences in their...

read more

The design of square nuts for anti-loosening purposes requires careful...

read moreFor exclusive deals and latest offers, sign up by entering your email address below.